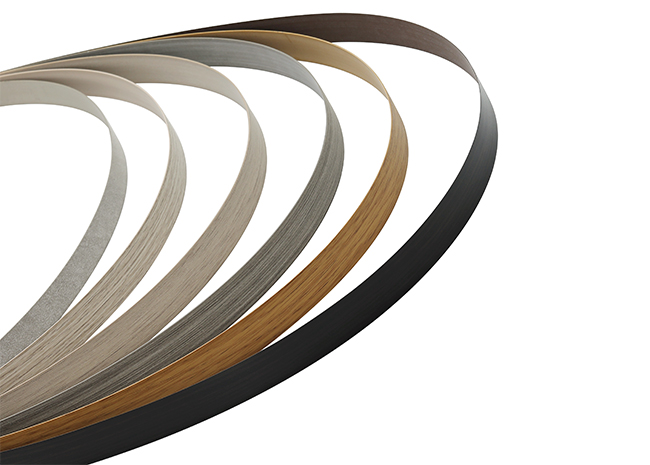

Edge Banding

The main function of edge banding is to protect, decorate and beautify the cross section of furniture boards, to prevent moisture and other factors in the environment from damaging the boards. It can prevent formaldehyde from volatilizing inside the boards and achieve decorative effects. Edge banding is mainly divided into PVC, ABS, acrylic, PP and other materials. The surface decoration has a variety of options such as solid color, wood grain, marble, cloth grain, etc. It can make the furniture show a clear wood grain and colorful overall effect.

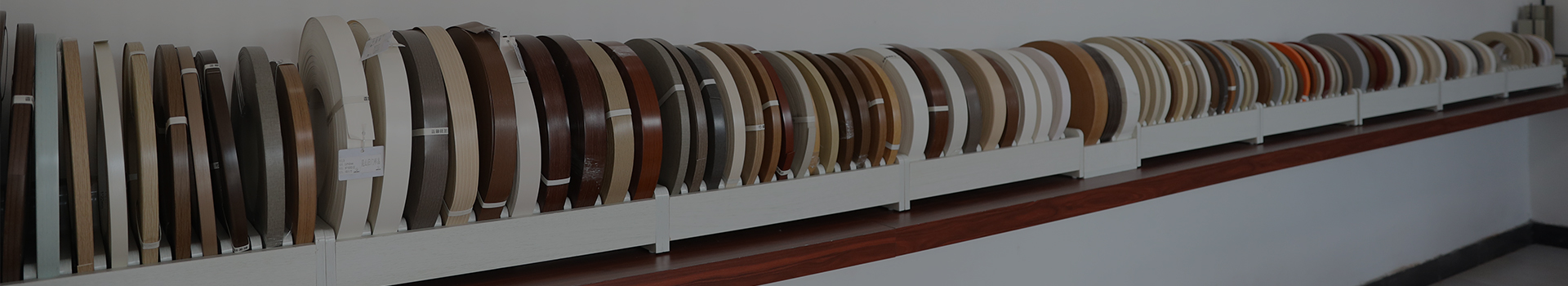

Chimeda is a professional edge banding manufacturer specializing in producing high-quality edge banding tapes for furniture, cabinets, doors, and interior decoration. With over 10 years of experience, we provide OEM/ODM solutions for global customers.

Chimeda is more than just an edge banding supplier — we are your long-term manufacturing partner. Our edge banding factory is equipped with state-of-the-art production lines including extrusion machines, printing units, embossing rollers, and slitting machines. We perform strict quality control throughout the entire process, from raw material selection to final packaging. Every edge banding roll is tested for strength, color consistency, and heat resistance before delivery.

Our strengths include:

1. Over 10 years of production experience

2. A full in-house production line with advanced extrusion and UV printing equipment

3. OEM/ODM service with flexible customization

4. Consistent color matching and strong adhesion

5. Fast lead time and stable supply capacity

6. Export experience with customers in over 30 countries

7. We support both small-batch orders and large-scale bulk production.

As an experienced edge banding manufacturer, Chimeda offers a comprehensive portfolio of products to meet different furniture design needs and surface finishes:

PVC Edge Banding: Versatile, durable, and easy to apply. Available in solid, wood grain, matte, and glossy finishes.

ABS Edge Banding: Environmentally friendly and ideal for sustainable furniture production.

Acrylic Edge Banding: High gloss and transparent options, perfect for a modern, luxurious look.

3D Edge Banding: Delivers depth and realism with a layered texture effect.

Aluminum Edge Banding: Strong, metallic edge protection for contemporary designs.

Wood Grain Edge Banding: Matches natural wood tones with realistic patterns.

Glossy & Matt Edge Banding: Available in a variety of colors and textures to suit different panel surfaces.

Solid Color Edge Banding: Clean and bold finish, ideal for minimalist or vibrant furniture.

Edge Banding Rolls: Supplied in standard or customized lengths for easy processing and storage.

All of our edge banding products are available in customizable widths, thicknesses, colors, and embossing styles.

Edge banding applies a thin layer of real wood veneer to panel edges, enhancing both appearance and performance.

01 / Enhanced Appearance

Creates a smooth, natural transition between surface and edge, delivering a solid-wood look with rich wood species and grain options.

02 / Design Flexibility

Easily supports curved edges and complex profiles. Available in multiple sizes such as 1mm, 3mm, 1/8 inch, and 1/5 inch.

03 / Cost-Effective Solution

Provides the appearance of solid wood at a lower cost, reducing material and labor expenses.

04 / Improved Durability

Protects edges from impact, moisture, and deformation, extending product lifespan.

05 / Eco-Friendly Choice

Uses wood resources efficiently, minimizing waste and supporting sustainable manufacturing.

06 / Easy Maintenance

Smooth, sealed edges resist dust and are easy to clean and maintain.

| Scenario | How Our Edge Banding Helps |

| Kitchen Cabinets & Wardrobes | Provides moisture protection, resists warping, and matches wood grain for seamless design. |

| Office & Commercial Furniture | Uniform finish, high durability in heavy-use environments. |

| Doors & Panel Edging | Clean edges, prevent moisture and formaldehyde from escaping boards. |

| DIY & Home Projects | Easy to apply, stylish effects, wide range of colors/textures for personal customization. |

Whether you are a furniture factory, interior design brand, or hardware distributor, Chimeda is your ideal edge banding manufacturer.

Tell us your project details — board type, required width, thickness, color/finish, quantity — and you’ll get:

→ A free sample to check the match and quality

→ A detailed quote with lead time and shipping options

→ Technical advice on choosing the right material & finish

Contact Us Or simply click the “Get Quote / Inquiry” button below to send us your specs — no obligation.

Q1: What is the primary purpose of edge banding?

A: It is used to cover the exposed sides of materials like plywood, particle board, or MDF. This enhances the appearance of the furniture, prevents moisture from seeping in, and reduces formaldehyde emission.

Q2: What are the common materials, and how do I choose?

A: PVC/ABS: Durable, cost-effective, and available in various colors. Ideal for kitchens and general furniture.

Acrylic (3D): Provides high transparency and depth, perfect for high-end modern designs.

Wood Veneer: Made from real wood for a natural look and feel, ideal for premium cabinetry.

Q3: Do I need to sand the edges before applying edge banding?

A: Yes. Sanding removes saw marks and dust, creating a smooth and slightly textured surface. This ensures maximum adhesion and prevents the banding from peeling off over time.

Q4: Can edge banding be painted?

A: Yes. Wood veneer can be stained or painted directly. For PVC/ABS, you must lightly sand the surface and apply a plastic-specific primer before painting to ensure the paint sticks.

Q5: Can old edge banding be removed?

A: Yes. Use a heat gun or a household iron to melt the adhesive. Once the glue is softened, gently peel off the banding. Any residue can be cleaned with a solvent or light sanding.

Q6: Is edge banding waterproof?

A: While materials like PVC/ABS are 100% waterproof, the overall protection depends on the sealing quality. For high-moisture areas (like bathrooms), using PUR adhesive is recommended for superior water resistance.

Q7: How can I tell if the quality is good?

A: Check for flexibility (it shouldn't turn white or crack when bent), color consistency (the surface should match the base color after trimming), and flatness (a flat back ensures even gluing).